06

2025

-

06

Optical Fiber Cage Manufacturer - Precision Manufacturing Enables High-Speed Optical Communication Systems

Author:

Chapter 1: Fiber Optic Cage Technical Definition and Core Functions

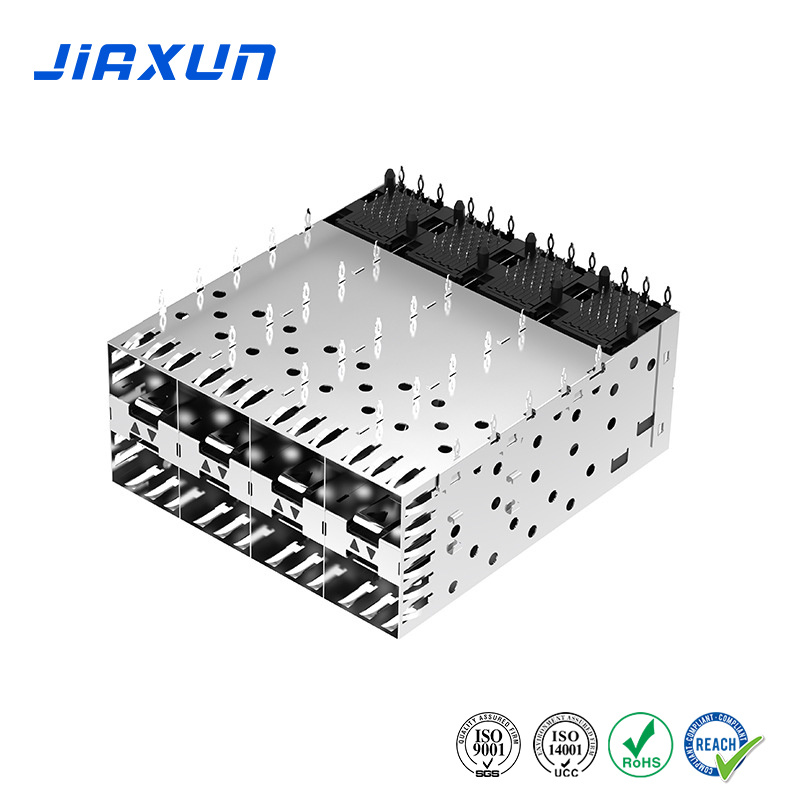

Fiber Optic Cage A fiber optic cage is a metal shielding structure used to secure optical modules and provide electromagnetic shielding, heat dissipation support, and mechanical protection. Its core functions include:

Electromagnetic Shielding (EMI) : Blocks external interference through a fully enclosed metal housing (such as stainless steel or copper alloy), ensuring that the optical module signal transmission bit error rate (BER) < 1E-12;

Heat Dissipation Optimization : Integrates heat sinks or thermally conductive silicone pads to reduce the operating temperature of the optical module by 10℃~15℃, extending its service life;

High-Density Adaptability : Supports standardized plug-and-play for optical module cages such as SFP and QSFP-DD. A single rack can deploy 144 ports, increasing space utilization by 50%.

Optical Module Cage (such as QSFP28 cage) as a subclass, is specifically designed for high-speed modules, supporting 56Gbps PAM4 signal transmission, and has become a key component in data centers and 5G equipment. China Fiber Optic Cage Manufacturers Through precision stamping and laser welding processes, the shielding effectiveness is increased to over 90dB, far exceeding industry standards.

Chapter 2: Fiber Optic Cage Performance Advantages and Market Value

Compared to traditional open-style optical module installation schemes, Fiber Optic Cage the core advantages are:

Signal Integrity Guarantee : The fiber optic shield uses a multi-point grounding design to suppress common-mode noise, reducing signal jitter by 30%;

High Reliability : Industrial-grade cages support wide-temperature operation from -40℃ to 85℃, with vibration tolerance up to 5Grms, suitable for vehicle-mounted and outdoor communication equipment;

Cost Effectiveness : Mass production makes the unit cost 25% lower than similar products in Europe and America, and it also supports customized mold opening (3-day sample delivery).

According to Grand View Research data, the global fiber optic cage market reached US$820 million in 2023, with a compound annual growth rate of 12.3%. Among them, China Fiber Optic Cage Manufacturers accounts for 45% of global production capacity, and 90% of the cage purchases of companies such as Huawei and ZTE come from the domestic supply chain.

Chapter 3: Diverse Application Scenarios and Industry Needs of Fiber Optic Cages

Fiber Optic Cage Applications cover the communication, data center, and industrial automation fields:

Data Center : 400G QSFP-DD cages support 51.2T switch networking, improve heat dissipation efficiency by 40%, and reduce the PUE value by 0.15;

5G Base Station : AAU equipment uses dustproof and waterproof (IP67) fiber optic shields to adapt to extreme climate environments;

Industrial Internet of Things : Corrosion-resistant plated (such as gold-plated, nickel-palladium alloy) cages are used in chemical plant PLC control cabinets, improving sulfurization resistance by 5 times;

Consumer Electronics : Ultra-thin cages (thickness <2mm) are used in 8K TV optical interface modules to meet the high-speed transmission requirements of HDMI 2.1.

In high-end Optical Module Cage manufacturing fields, leading manufacturers have achieved a fully digital "design-simulation-mass production" process, supporting customers' customized impedance matching (100Ω±5%) and insertion loss compensation schemes.

Chapter 4: Fiber Optic Cage Manufacturing Process and Quality Control

The manufacturing of fiber optic cages covers materials engineering, precision processing, and automated assembly:

Material Selection :

The housing uses SPCC cold-rolled steel or C7025 copper alloy, with conductivity >90% IACS;

The contact plating thickness ≥0.2μm (gold) or ≥1.5μm (tin) ensures a 5000-time plug-and-play life.

Precision Stamping :

High-speed stamping machine (600 times/minute) forms the cage body, with tolerance control of ±0.01mm;

Laser cutting windows, positioning accuracy ±5μm.

Surface Treatment :

Electroplating/chemical plating processes improve corrosion resistance, salt spray test >96 hours;

Insulating coatings (such as PTFE) are applied to high-speed cages to reduce crosstalk to -50dB.

Automated Assembly :

Robot welding ensures the airtightness of the shield, with a leakage rate <10⁻³ Pa·m³/s;

The visual inspection system 100% checks the pin coplanarity (<0.05mm) and contact resistance (<10mΩ).

In response to environmental regulations, leading fiber optic cage manufacturers have introduced cyanide-free electroplating and wastewater recycling systems, reducing heavy metal emissions by 90%, and have passed IATF 16949 certification to serve automotive electronics customers.

Conclusion

In the era of the evolution of optical communication to 800G/1.6T, fiber optic cages have been upgraded from "passive components" to "guardians of high-speed interconnection performance." China Fiber Optic Cage Manufacturers Leveraging its precision mold development capabilities (accuracy up to ±1μm), flexible production lines (supporting a daily production capacity of 500,000 units), and rapid iteration advantages, the company is becoming a strategic partner for global optical module manufacturers. In the future, with the popularization of silicon photonics and LPO (linear direct drive) architecture, the integration and signal density of fiber optic shields will further improve, and the technological dividend of "Made in China" will continue to be released.

06

2025-06

06

2025-06

SFP Optical Module—The Core Engine and Market Opportunities of High-Speed Network Interconnection

06

2025-06

SFP Optical Module—The Core Engine and Market Opportunities of High-Speed Network Interconnection

06

2025-06

Fiber Optic Modules — Core Technology Analysis and Market Outlook for Driving the Digital Future

04

2025-06

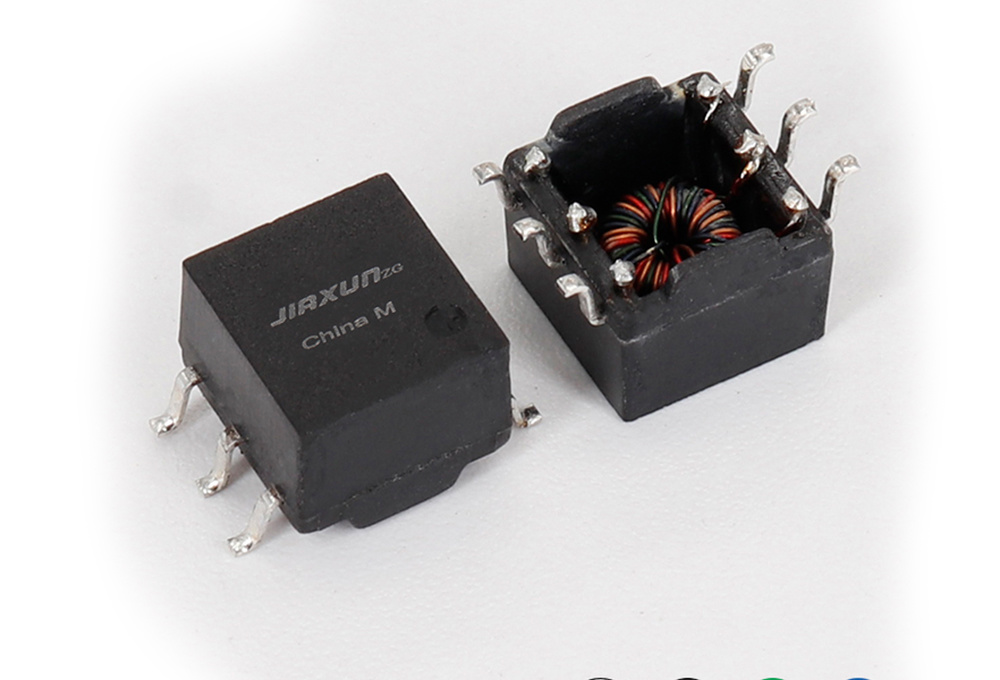

China SMD LAN Transformer Supplier: Technology Leader in the Wave of Miniaturization

04

2025-06

04

2025-06

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy