04

2025

-

06

Ethernet Transformer Manufacturer: China's Smart Manufacturing Drives the Global High-Speed Interconnection Revolution

Author:

I. Ethernet Transformer Technical Architecture and Performance Breakthroughs

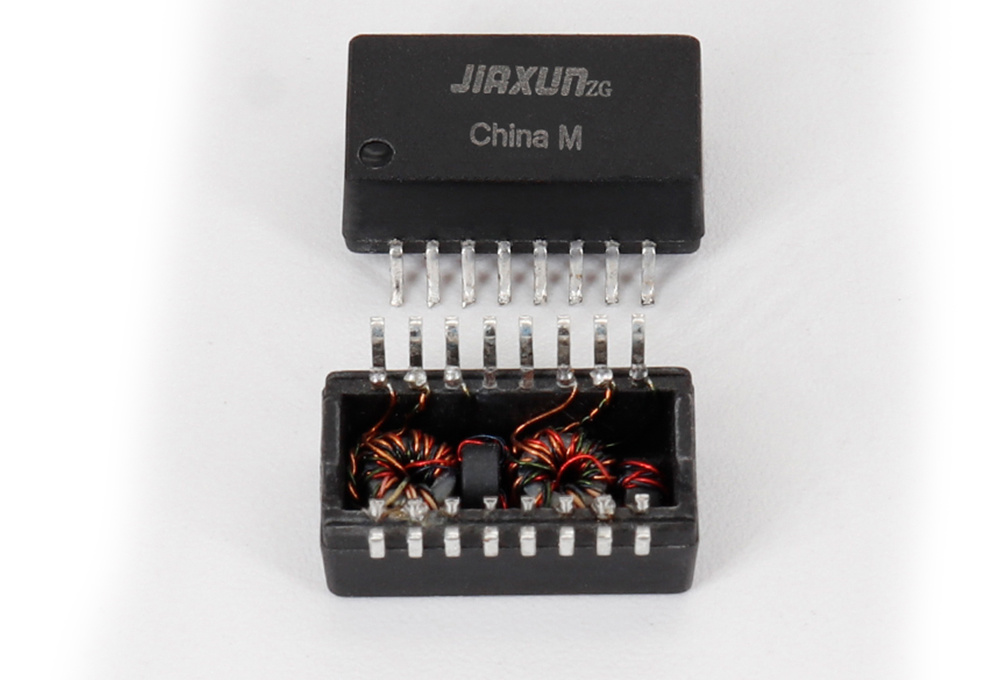

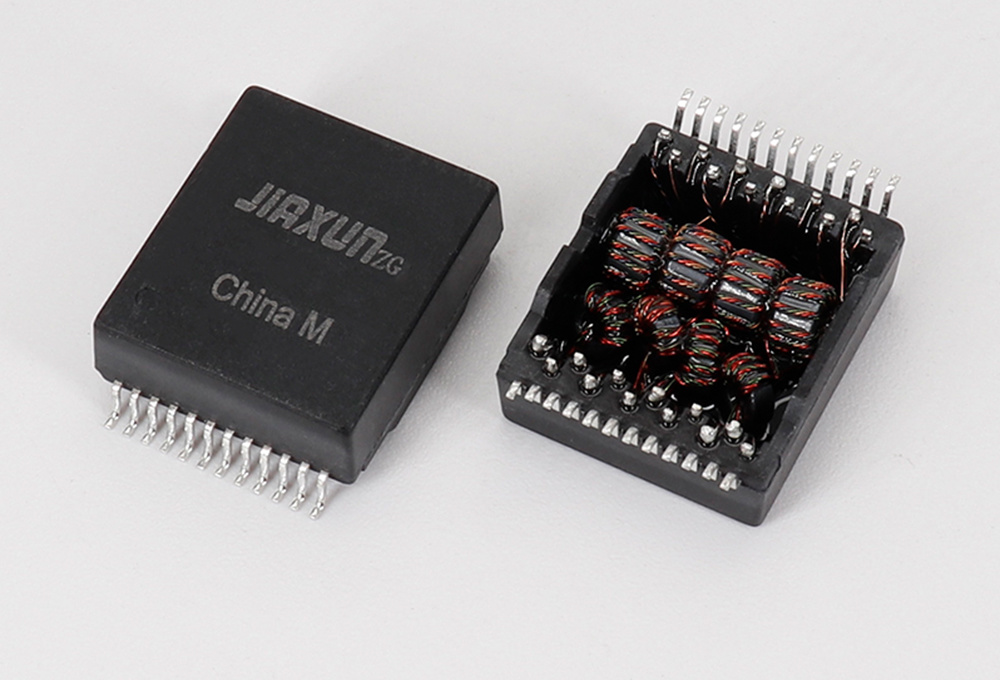

1.1 Core Component for Physical Layer Signal Processing

Ethernet Transformer As a key implementer of the IEEE 802.3 standard, Ethernet Transformer undertakes three core functions:

Electrical Isolation : Achieves 1500Vrms/min withstand voltage (IEC 62368-1 certified) through a triple insulation system, eliminating the risk of ground potential difference between devices

Impedance Matching : Utilizes a 4×2 balanced winding structure, maintaining a differential impedance accuracy of 100Ω±3% (measured return loss ≤-26dB)

Electromagnetic Compatibility : Common Mode Rejection Ratio (CMRR) ≥45dB within the 30MHz-1GHz frequency band

Leading Ethernet transformer manufacturers have implemented fully automatic magnetic core winding processes, achieving winding accuracy of ±0.3 turns with 0.02mm enameled wire, controlling insertion loss to within 0.25dB.

1.2 Technical Parameter Evolution Roadmap

Compared to traditional products, the new generation of Ethernet transformers achieves four major upgrades:

Parameter | 2015 Level | 2024 Benchmark | Improvement Margin |

Operating Frequency | 100MHz | 250MHz | 150% |

Temperature Range | -40~+85℃ | -55~+125℃ | Expanded 40℃ |

Surge Protection Level | 4kV ESD | 8kV ESD | 100% |

Production Yield | 92% | 99.8% | 8.5% |

II. China's Ethernet transformer manufacturers Global Competitiveness

2.1 Technical R&D System Restructuring

China Ethernet transformer manufacturers breaks through technical barriers through three major innovations:

Material Engineering : Developed nanocrystalline alloy magnetic cores (initial permeability ≥15000), reducing losses by 40%

Process Revolution : Fully automatic visual inspection system achieves 0.01mm-level defect recognition

Integrated Design : Integrates TVS diodes and common-mode chokes into a single module (volume reduced by 60%)

Leading enterprises represented by Jiaxun Intelligent, with their industrial-grade products, have passed 48 stringent tests (including MIL-STD-810G vibration, IEC 60068-2-11 salt spray), becoming designated suppliers for 5G base stations.

2.2 Smart Manufacturing and Supply Chain Advantages

China Ethernet transformer manufacturers A unique production system has been built:

Digital Twin Factory : AI simulation optimizes winding parameters, shortening new product development cycles from 12 weeks to 3 weeks

Flexible Production Line : Can switch to produce 30 different product specifications daily

Zero Inventory System : Relies on the Yangtze River Delta/Pearl River Delta supply chain clusters for 48-hour rapid delivery

Customs data for 2023 shows that China's Ethernet Transformer exports accounted for 62% of the global total, with the share of high-end products (10Gbps+) increasing from 15% to 38%.

III. Multi-Scenario Solutions and Industry Empowerment

3.1 Industrial IoT Scenario

Addressing Industrial 4.0 demands, China's Ethernet transformer manufacturers provides:

Anti-Interference Design : EN 55032 Class A certified, electromagnetic radiation <30dBμV/m

Wide Temperature Range Support : Cold start time at -55℃ <2 seconds (traditional products require 5 seconds)

Vibration-Resistant Structure : Withstands 15G mechanical shock (IEC 61373 standard)

After adopting customized products, a smart mine project saw a 73% drop in underground switch failure rates, with MTBF exceeding 60,000 hours.

3.2 Data Centers and 5G Infrastructure

Solutions supporting 25G/100G high-speed Ethernet:

Low-latency design: Transmission delay <10ns (60% optimization compared to traditional products)

High-density layout: 256 ports can be deployed in a 1U rack

Energy-saving features: Power consumption per port reduced to 0.15W (ERPS protocol optimization)

China Mobile's 2023 test report shows that 5G fronthaul equipment using domestically produced transformers reduced bit error rate from 10⁻⁵ to 10⁻⁷.

3.3 Smart Automotive Electronics

Automotive-grade Ethernet Transformer features:

AEC-Q200 Grade 1 certified (-40~+125℃)

Supports 10Gbps T1S in-vehicle Ethernet protocol

Anti-sulfuration design (JASO D001 standard)

After new energy vehicle manufacturers adopted domestically produced components for their in-vehicle gateway modules, the EMC certification pass rate increased from 85% to 98%.

IV. Industry Trends and Procurement Strategy

4.1 Technology Evolution Directions

High frequency : Core materials supporting 800G Ethernet (operating frequency ">=1GHz)

Intelligence : Integrated temperature/humidity sensors to enable fault prediction (MTTR reduced by 70%)

Green Manufacturing : Lead-free soldering process (compliant with RoHS 3.0)

The gallium nitride-based transformer jointly developed by Huawei HiSilicon and Chinese Academy of Sciences has achieved 0.18dB insertion loss at an operating frequency of 500MHz.

4.2 Supplier Selection Strategy

Purchasers should establish a three-dimensional evaluation system:

Technical Qualifications : Verify ISO/TS 16949, IECQ QC 080000 system certifications

Delivery Capability : Validate the feasibility of 72-hour delivery for urgent orders

Customization Depth : Evaluate customization capabilities such as impedance tolerance ("">2%)") and packaging forms

A cloud computing giant, by prioritizing China, Ethernet transformer manufacturer , increased the single-rack deployment density in its data centers by 40% and saved 12 million RMB in annual operation and maintenance costs.

Chinese Manufacturer Competitiveness Matrix

Indicator | International Competitors | Leading Chinese Manufacturers | Advantage Gap |

Unit Production Cost | $0.38 | $0.22 | -42% |

Custom Development Cycle | 6 weeks | 2 weeks | -67% |

On-time Delivery Rate | 88% | 99.5% | +11.5% |

Patent Holdings (2023) | 1200 items | 3800 items | +217% |

Ethernet Transformer Manufacturer

04

2025-06

04

2025-06

04

2025-06

30

2025-05

In-depth Comparison of LAN Transformer Suppliers: 7 Key Parameters Affecting Device Lifespan

30

2025-05

30

2025-05

Soaring Demand for Customized Ethernet Transformers: How Can Chinese Manufacturers Respond Quickly?

29

2025-05

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy