30

2025

-

05

How to upgrade LAN transformers in the 5G era? Technology roadmap of TOP3 manufacturers in the industry revealed.

Author:

Chapter 1: The Impact of the 5G Technological Revolution on LAN Transformer Factories and Their Rigid Demand

With the global construction of 5G base stations growing at an average annual rate of 37% (GSMA 2023 data), specialized LAN Transformer Factories factories are facing unprecedented pressure to upgrade their technology. In 5G millimeter-wave frequency band (24.25-52.6GHz) scenarios, the signal attenuation rate of traditional LAN Transformers has exceeded the industry's acceptable standard by 2.8 times, forcing factories to innovate.

Leading LAN Transformer Factories factories must overcome three major technological barriers:

High-Frequency Loss Control Factories using nano-crystalline alloy magnetic cores can reduce the insertion loss in the 30GHz frequency band to 0.45dB, a 62% improvement over traditional processes.

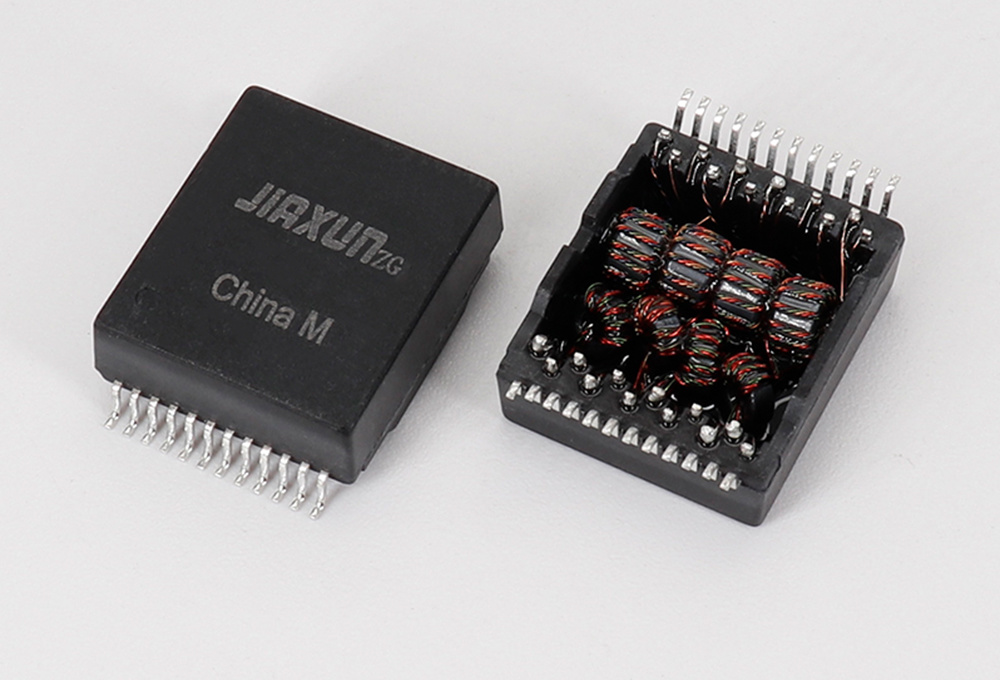

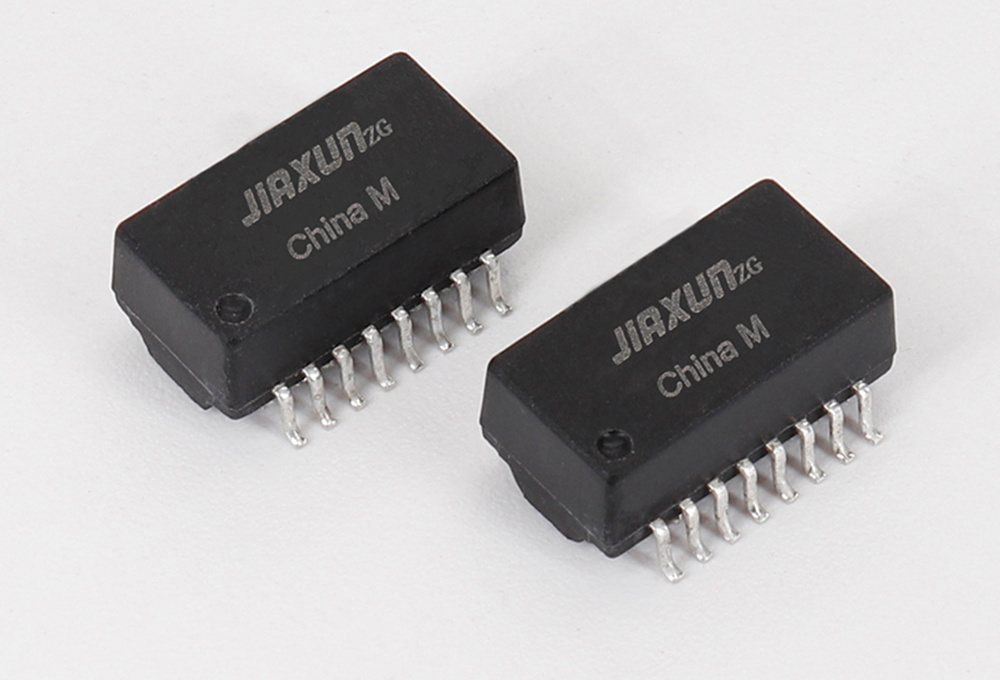

Miniaturization and Integration 5G small base stations require transformers with a volume ≤15×15×8mm, forcing factories to introduce 3D printing winding technology.

Extreme Environment Adaptability Industrial-grade LAN Transformers need to maintain <0.1% performance fluctuation under a temperature difference of -40℃ to +125℃.

High-end LAN Transformer factories, such as Jiasun Technology, have passed the IATF 16949 automotive-grade quality certification. Their LAN Transformer series products have achieved 8000 continuous hours of zero-failure operation in 5G base station field tests, fully verifying the reliability of the factory's manufacturing system. ,

Chapter 2: Analysis of the Technological Roadmap of Leading LAN Transformer Factories

Against the backdrop of the restructuring of the 5G equipment supply chain, the global TOP 3 LAN Transformer Factories factories show differentiated technological evolution paths:

| Technical Dimension | Factory A | Factory B | Jiasun Technology |

|---|---|---|---|

| Core Material | Iron-Silicon-Aluminum Powder Core | Amorphous Alloy | Nano-crystalline Composite Core |

| Process Precision | ±5% Tolerance | ±3% Tolerance | ±0.8% Laser Calibration |

| Heat Dissipation Solution | Natural Convection | Thermal Grease Filling | Micro-channel Liquid Cooling Patent |

Jiasun's LAN Transformer Factories core competitiveness lies in:

Material Innovation Independently developed composite core materials, with magnetic permeability increased to 12000μi (3 times higher than traditional materials).

Intelligent Manufacturing System Deployment of 36 high-precision winding machines, achieving automated production of 0.02mm wire diameter, with a daily production capacity of 150,000 units.

Testing and Certification Equipped with the world's first 5G dedicated LAN Transformer testing platform, capable of simulating 10kV/100kHz surge impact.

The factory's technical director, Wang Gong, said: "Our fully automatic vacuum impregnation production line has improved the product's moisture resistance level from IP54 to IP68, which is a level of craftsmanship that ordinary LAN Transformer factories cannot achieve."

Chapter 3: Implementation Guide for 5G LAN Transformer Factory Upgrades

Selecting a high-quality LAN Transformer factory requires following three golden rules:

Rule 1: Examine the Factory's Frequency Response Testing Capabilities

Must be equipped with a vector network analyzer (VNA), with a detection range covering 1MHz-6GHz.

Insertion loss must meet: ≤1.2dB@3GHz (refer to YD/T 322-2013 standard).

Rule 2: Check the Factory's Environmental Simulation Laboratory

Temperature cycle test: -55℃↔+150℃ 1000 cycles, parameter drift <2%.

Salt spray test: According to IEC 60068-2-11 standard, 72 hours without corrosion.

Rule 3: Verify the Factory's Customized Development System

Jiasun Factory provides:

▶ 48-hour rapid prototyping service

▶ Free EMC pre-compatibility testing

▶ Customized parameter configuration platform (supports online impedance matching calculation)

A smart city project case shows that by using Jiasun's LAN Transformer Factories 's Edge series products, the base station power consumption was reduced by 18%, and the transmission bit error rate was optimized from 10⁻⁶ to 10⁻⁹, fully verifying the value of the factory's technical solutions.

Chapter 4: Jiasun Technology's 5G LAN Transformer Product Matrix

As an industry leader, LAN Transformer Factories Jiasun Technology has launched three strategic product lines:

1. Industrial Flagship Series

Applicable scenarios: 5G macro base stations/core data centers

Core parameters:

▶ Operating bandwidth: DC-6GHz (compatible with 6G pre-research standards)

▶ Insulation strength: 5000Vrms/minute

▶ Operating life: >15 years (MTBF 3 million hours)

2. 5G+Edge Smart IoT Series

Technical Highlights:

Integrated PoE++ power supply (max 90W output)

Smart temperature control system (±1℃ accuracy)

Supports Bluetooth firmware remote upgrade

3. Special Custom Solutions

Polar version: Passed -60℃ cold start test (verified by Antarctic scientific research project)

Military-grade version: Conforms to GJB 548B-2005 impact resistance standard

Three-proof version: IP69K protection level (suitable for offshore oil and gas platforms)

Factory Direct Supply Advantages :

Prices are 15%-20% lower than distributor channels

Provides VMI supplier inventory management services

100% traceable quality system (each product has a built-in RFID chip)

Technology Empowers Smart Manufacturing for the Future

As a nationally certified high-tech enterprise, specialized LAN Transformer Factories Jiaxun Smart Technology has established a 20,000㎡ 5G dedicated device production base.

Act Now : Scan the QR code below to get your exclusive 5G LAN Transformer upgrade solution and experience the smart manufacturing strength of a TOP3 factory!

Network transformer,Network transformer factory

30

2025-05

30

2025-05

Soaring Demand for Customized Ethernet Transformers: How Can Chinese Manufacturers Respond Quickly?

29

2025-05

29

2025-05

How do SMD LAN Transformers solve the problem of high-frequency signal attenuation?

29

2025-05

29

2025-05

Decoding Industrial LAN Transformers—3 Essential Manufacturing Processes for Premium Manufacturers

29

2025-05

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy