29

2025

-

05

Must-Read for Suppliers of LAN Magnetic Components - New Standards for EMC and Surge Protection in 2024

Author:

Compliance Upgrades and Technological Iteration Reshape Industry Competition

Chapter 1: Background and Impact of 2024 EMC and Surge Protection Standard Updates

With the rapid development of 5G communication, Industrial Internet of Things (IIoT), and new energy equipment, electromagnetic compatibility (EMC) and surge protection capabilities have become core indicators for measuring the reliability of network equipment. In 2024, the International Electrotechnical Commission (IEC) and national regulatory agencies will simultaneously upgrade industry standards, placing LAN Magnetic Component Suppliers under higher demands:

Reasons for Standard Upgrades :

High-Frequency Challenges : The popularization of technologies such as 5G millimeter wave and Wi-Fi 7 has extended the operating frequency band of devices to 10 GHz, making it difficult for traditional LAN Transformers and filters to meet the EMC performance requirements of new scenarios;

Increased Environmental Risks : Frequent lightning disasters worldwide have increased the surge protection level in industrial scenarios from ±2kV to ±4kV, forcing LAN Transformers insulation layers and LAN Filters to upgrade their transient response capabilities.

Industry Impact :

Increased Technological Barriers : Small and medium-sized suppliers face the risk of market elimination due to insufficient R&D investment;

Increased Cost Pressure : Fully automated production processes and high-specification materials have become standard, accelerating supply chain integration.

As a core component supplier, only by keeping up with standard iterations can we seize the opportunity.

Chapter 2: Technical Requirements Analysis under New Standards

The 2024 new standards for LAN Transformers and LAN Filters have put forward clear technical indicators and testing requirements:

EMC Performance Upgrade :

LAN Transformers : The common-mode rejection ratio (CMRR) has been increased from ≥60dB to ≥70dB, requiring the use of nanocrystalline magnetic cores and multilayer shielded winding processes;

LAN Filters : Insertion loss in the 1GHz band needs to reach -40dB, and it needs to support multi-band superimposed interference suppression (such as 5G+Wi-Fi 6E).

Surge Protection Enhancement :

Insulation Withstanding Voltage : The withstand voltage level of industrial-grade LAN Transformers has been increased from 3kV to 6kV;

Response Speed : LAN Filters need to integrate TVS diodes, and the surge response time ≤1ns.

Stricter Testing and Certification :

Added high and low temperature cycle tests (-40℃~85℃) to verify the all-environment stability of components;

Mandatory requirement for third-party laboratories to provide multi-scenario compatibility reports (such as vehicle-mounted, outdoor base stations).

These changes require LAN Magnetic Component Suppliers innovation across the entire chain from design to production; low-cost strategies alone are no longer viable.

Chapter 3: Supplier Response Strategies and Technological Upgrade Solutions

To meet the new standards, LAN Magnetic Component Suppliers requires concerted efforts in R&D, production, and compliance:

R&D: Material and Structural Innovation

Magnetic Core Material : Using high-Bs nanocrystalline alloys to reduce high-frequency losses in LAN Transformers;

Circuit Topology : Optimizing the LC parameters of LAN Filters to improve broadband noise suppression capabilities.

Production: Process and Quality Control Upgrades

Introducing fully automatic winding machines and vacuum impregnation processes to ensure the consistency of interlayer insulation of LAN Transformers;

100% online withstand voltage testing to eliminate the risk of surge protection failure.

Compliance: Efficient Certification Path

Jointly build a test database with third-party laboratories to shorten the certification cycle;

Use simulation tools (such as ANSYS HFSS) to predict EMC performance and reduce trial-and-error costs.

Case : A leading supplier used the above strategies to reduce the product certification cycle from 120 days to 60 days, increasing market share by 15%.

Chapter 4: Jiaxun Company—A Full-Scenario Solution Expert under New Standards

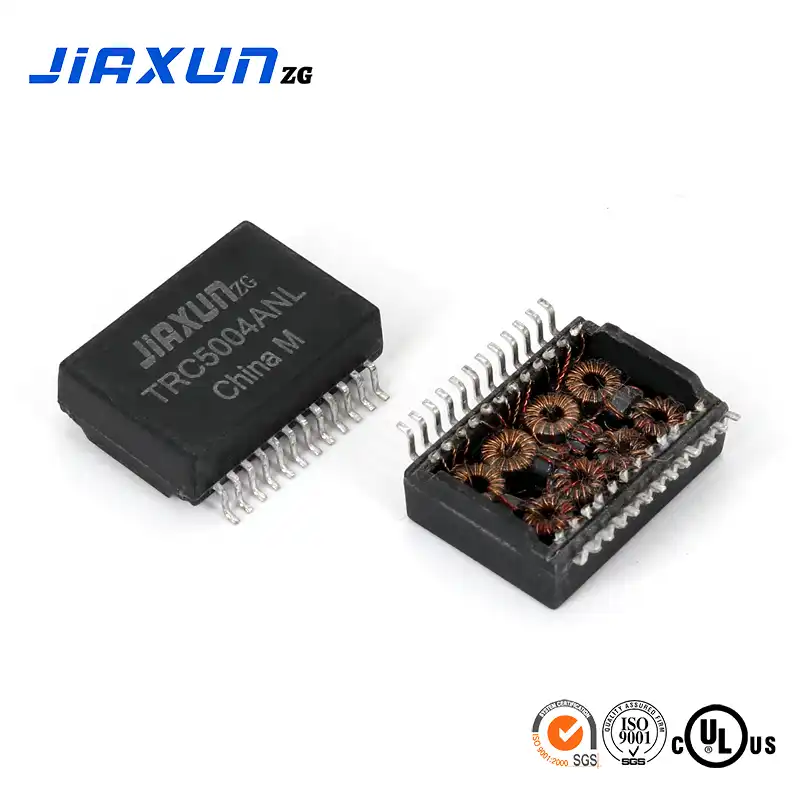

As an industry-leading LAN Magnetic Component Suppliers Jiaxun Company uses technological leadership and full-chain services to help customers easily cope with standard upgrades:

Technological Advantages

Patented Magnetic Core Technology : LAN Transformers CMRR≥75dB, exceeding industry standards by 7%;

Intelligent Filtering Design : LAN Filters Integrated self-recovery fuse, surge tolerance up to ±6kV.

Benchmark Product Recommendation

JX Industrial Grade LAN Filters :

Insertion loss -45dB@1GHz, supporting ultra-wideband DC-10GHz;

Passed CISPR 32 Class B certification, suitable for new energy charging piles and smart grids.

JX LAN Transformers :

6kV insulation withstand voltage, -40℃~125℃ wide temperature operation;

Compatible with PoE++ (90W) power supply, reducing wiring costs by 30%.

Success Cases

Case 1 Customized an EMC solution for a European photovoltaic inverter manufacturer, passing EN 55032 certification on the first attempt.

Case 2 Assisted a domestic high-speed rail on-board communication system in withstanding 10kV lightning surge, reducing the failure rate to 0.01%.

Service Commitment

Free Pre-test Support Provide EMC simulation reports and surge protection scheme pre-review.

High-Speed Certification Channel Expedited testing with partner laboratories, completing all certifications within 30 days.

Conclusion and Call to Action

The new 2024 standards are both a challenge and LAN Magnetic Component Suppliers an opportunity to reshape industry status. Jiaxun Company, with its strong technical capabilities and agile service capabilities, provides customers with one-stop support from compliance consulting to mass production delivery.

Take Action Now :

Send an email to 【sales4@jiaxunzg.cn】to request a free sample and experience the superior performance!

LAN Magnetic Component Supplier,LAN Magnetic Supplier,LAN Transformer,LAN Filter

30

2025-05

30

2025-05

Soaring Demand for Customized Ethernet Transformers: How Can Chinese Manufacturers Respond Quickly?

29

2025-05

29

2025-05

How do SMD LAN Transformers solve the problem of high-frequency signal attenuation?

29

2025-05

29

2025-05

Decoding Industrial LAN Transformers—3 Essential Manufacturing Processes for Premium Manufacturers

29

2025-05

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy