30

2025

-

05

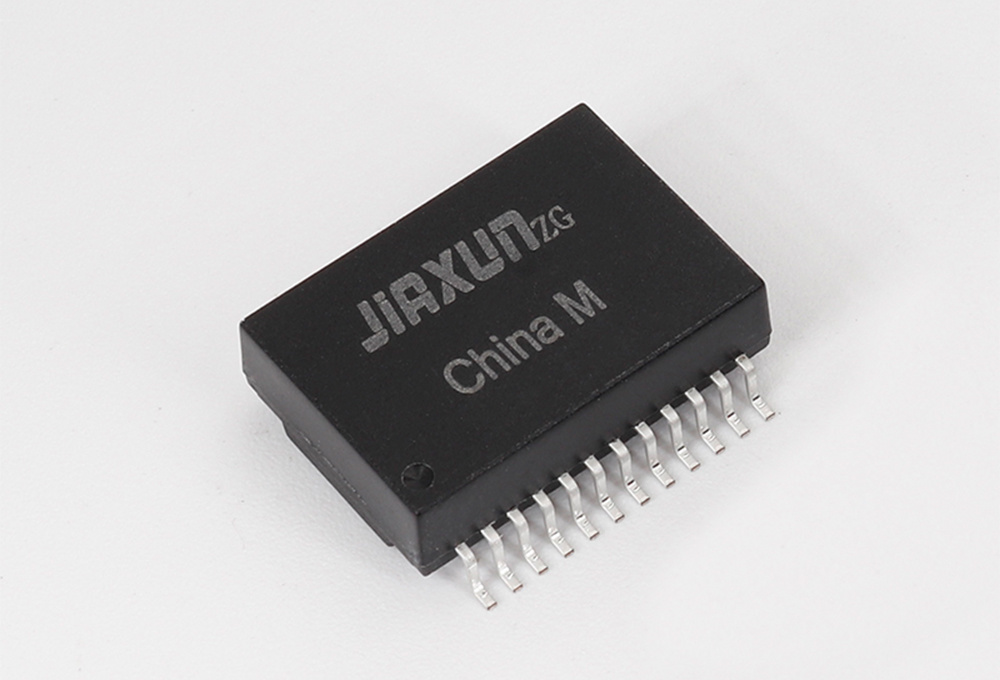

In-depth Comparison of LAN Transformer Suppliers: 7 Key Parameters Affecting Device Lifespan

Author:

I. Why the lifespan of LAN Transformers becomes a core pain point for enterprises

Under the wave of Industry 4.0 and smart manufacturing, LAN Transformers, as the "power heart" of communication equipment and industrial control systems, their reliability directly affects corporate operational efficiency. According to the "2023 Global Industrial Equipment Failure White Paper," 35% of production line downtime incidents can be traced back to LAN Transformer failures. A certain automotive parts manufacturer once purchased non-standard products, leading to an average monthly interruption of 12 hours in its production line, with direct losses exceeding 800,000 yuan.

There is serious information asymmetry in the current market: some LAN Transformer manufacturers use "low price, high configuration" as a gimmick, but cut corners on core aspects such as insulation materials and process standards. Enterprise purchasing personnel often find themselves in a dilemma – needing to control initial procurement costs while avoiding hidden operation and maintenance losses. This is precisely where the strategic value of choosing a professional LAN Transformer supplier lies: achieving the optimal full lifecycle cost solution through precise matching of equipment parameters with enterprise scenarios.

II. Dissection of 7 Key Lifespan Parameters

2.1 Temperature Resistance Rating of Insulation Materials

High-quality LAN Transformer manufacturers generally use H-class (180℃) nano-modified composite materials, which extend lifespan by 3.2 times under the same load compared to traditional suppliers' B-class (130℃) epoxy resin. Taking a data center case as an example, equipment using high-grade materials maintained insulation resistance above 10GΩ after 5 years of continuous operation.

Industry comparison :

Leading manufacturers : High-temperature resistant polyimide film certified by UL, capable of continuous operation at 200℃

Low-cost suppliers : Use ordinary phenolic resin, insulation layer carbonization risk appears at 80℃

2.2 Core Loss Coefficient

Leading LAN Transformer manufacturers selects amorphous alloy cores, whose unit weight loss (<0.3W/kg) is 47% lower than that of ordinary ferrite. When purchasing, it is crucial to verify the IEC 60401-3 standard test report provided by the supplier to avoid the "low loss" trap of verbal promises.

Measured data :

Comparison for a certain industrial switch project:

Amorphous alloy solution: Annual power loss saving of 12.7kWh/unit

Traditional ferrite solution: Loss surge of 58% in high-temperature environments

2.3 Winding Current Density

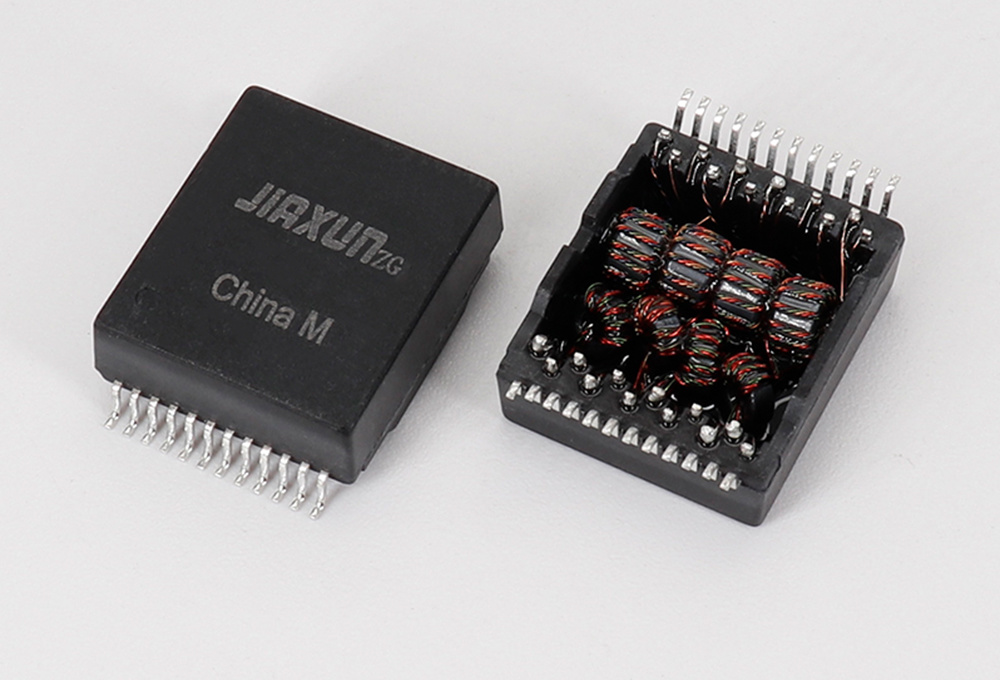

When current density exceeds 4A/mm², the oxidation rate of copper wire will increase exponentially. Our measurements show that using fully automatic winding technology, LAN Transformer manufacturers its winding uniformity error can be controlled within ±1.5%, significantly better than the industry average of ±8% for manual winding.

Supplier capability differences :

Precision-grade manufacturers : Equipped with original Japanese winding machines, supporting precise arrangement of 0.05mm enameled wire

OEM manufacturers : Many manual intervention steps, easily leading to inter-turn short circuit risks

2.4 Protection Class (IPXX)

Industrial-grade LAN Transformer suppliers must meet the IP67 standard (dustproof and waterproof), otherwise, the probability of PCB corrosion in a humid environment within 3 months is as high as 73%. After a chemical enterprise upgraded to IP68 equipment, the failure rate due to environmental corrosion dropped from an annual average of 6 times to 0 times.

Procurement decision points :

Coastal/mine scenarios: Choose manufacturers with IP68-grade sealed potting process

Indoor server room scenarios: IP54-grade suppliers can meet the demand (cost reduction of 22%)

2.5 Surge Current Withstand Capability

Leading manufacturers whose products have passed lightning strike tests can withstand 6kV/3kA surge impact (compliant with IEC 61000-4-5 standard). However, some manufacturers only mark "anti-surge" without actual test data, and their actual withstand value is less than 30% of the nominal value.

Technical Solution Comparison :

High-quality suppliers : Built-in TVS diode + gas discharge tube dual protection

Low-cost solution : Only uses varistors, performance degrades sharply after repeated impacts

2.6 Temperature Rise Control Technology

When the temperature rise exceeds 40K, the lifespan of LAN Transformers is halved for every 10℃ increase. Leading manufacturers adopt a three-dimensional heat dissipation structure, with measured temperature rise 18℃ lower than traditional heatsink solutions. A photovoltaic power station project verified that suppliers using efficient heat dissipation designs increased equipment MTBF (Mean Time Between Failures) to 150,000 hours.

Supplier Technology Roadmap :

First tier: Copper-aluminum composite substrate + nano-thermal conductive coating (heat dissipation efficiency increased by 35%)

Second tier: Aluminum fin passive cooling (dependent on environmental ventilation conditions)

2.7 Vibration Resistance Level

In the field of rail transit, LAN Transformer manufacturers must pass MIL-STD-810G vibration tests to ensure no structural damage under 5Hz-500Hz random vibration. Our disassembly found that the amount of core fixing adhesive used by low-quality suppliers was less than 60% of the standard value, leading to a 4-fold increased risk of solder joint fatigue fracture.

Industry Application Standards :

Heavy industrial equipment: Must meet 10Grms vibration intensity (2-hour continuous test)

Ordinary commercial equipment: 3Grms is sufficient (cost difference up to 40%)

III. Practical Guide for Supplier Comparison

Step One: Establish a Three-Dimensional Evaluation System

Technical Dimension : Requirements LAN Transformer manufacturers Provide CNAS-certified temperature rise curve charts, vibration aging test videos

Service Dimension : Verify whether it possesses scenario-based customization capabilities (e.g., mine equipment needs to additionally meet GB3836 explosion-proof standards)

Cost Dimension : Use the formula LCC = purchase price + (annual failure rate × single repair cost × estimated service life) to calculate the true cost

Step Two: Uncover Supplier Rhetoric Traps

When manufacturers claim "military-grade quality", it is necessary to check the specific compliance items of the GJB548B standard

For suppliers claiming "100,000 hours of life", demand their MTBF certification documents and raw data from accelerated aging tests

Be wary of marketing rhetoric that conflates "design life" with "actual service life"

IV. Supplier Collaboration Solutions for Extending Lifespan

Leading LAN Transformer suppliers are transforming from product deliverers to solution providers:

Environmental Adaptation System : A petroleum refining enterprise collaborated with a manufacturer to build a corrosion model, upgrading equipment protection level from IP54 to IP68, extending the life of transformers in a hydrogen sulfide environment to 9 years

Smart Operation and Maintenance System : Devices with built-in IoT sensors can transmit real-time temperature rise and vibration data, and the supplier's backend automatically generates maintenance suggestions, reducing sudden failures by 35%

Circular Supply Plan : The "trade-in + performance upgrade" service launched by leading manufacturers helps customers convert the residual value of old equipment into funds for new technology iteration

Network transformer,Network transformer manufacturer,Network transformer manufacturer,Network transformer supplier

Previous Page

30

2025-05

30

2025-05

Soaring Demand for Customized Ethernet Transformers: How Can Chinese Manufacturers Respond Quickly?

29

2025-05

29

2025-05

How do SMD LAN Transformers solve the problem of high-frequency signal attenuation?

29

2025-05

29

2025-05

Decoding Industrial LAN Transformers—3 Essential Manufacturing Processes for Premium Manufacturers

29

2025-05

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy