29

2025

-

05

Decoding Industrial LAN Transformers—3 Essential Manufacturing Processes for Premium Manufacturers

Author:

Chapter 1: Industrial Grade LAN Transformers Basic Understanding

Industrial-grade LAN Transformers serve as core components in modern industrial communication systems, undertaking key functions such as signal isolation, impedance matching, and electromagnetic interference suppression. Compared to ordinary LAN Transformers, their design standards are more stringent, requiring wide-temperature operation from -40℃ to 125℃, IP67 protection rating, and a lifespan exceeding 100,000 hours.

Taking RJ45 LAN Transformers as an example, industrial-grade products must ensure signal integrity in Gigabit Ethernet transmission while also withstanding challenges from complex environments such as dust, vibration, and humidity. These devices are widely used in scenarios such as PLC control in smart factories, in-vehicle communication in rail transit, and remote monitoring in new energy power stations. For instance, in an automated production line, industrial-grade RJ45 LAN Transformers must ensure stable data interaction between equipment and cloud servers under 24/7 operation, placing extremely high demands on the manufacturer's material selection and process precision.

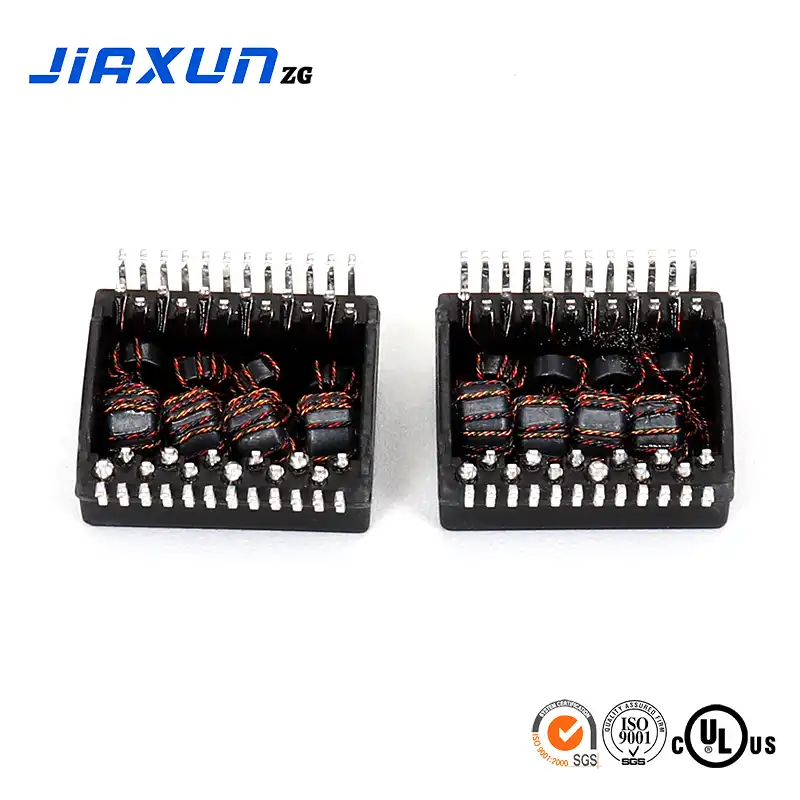

As a professional LAN Transformer Manufacturer Jiaxun Company has been deeply involved in the industrial field for 15 years. Its products have passed global certifications such as UL, CE, and RoHS, serving over 200 industrial customers with a failure rate below 0.1%.

Chapter 2: In-depth Analysis of Three Core Production Processes

1. Precision Winding Process: The Foundation of Performance RJ45 LAN Transformers Winding precision directly determines signal transmission efficiency and bandwidth limits. Jiaxun uses fully automatic winding machines (precision ±0.005mm), combined with high-purity oxygen-free copper wire, to control insertion loss within 0.8dB, exceeding the industry average by 30%. In Gigabit Ethernet applications, this process reduces signal reflection and ensures the stability of 10Gbps high-speed transmission.

2. Multi-layer Insulation Packaging Technology: Ultimate Protection in Extreme Environments

In industrial settings, RJ45 interfaces are often exposed to oil stains and salt spray. Jiaxun pioneered the "epoxy resin + silicone composite packaging" process, combined with a metal shielding layer design, expanding the product's temperature range to -55℃~150℃ and passing a 5kV withstand voltage test. In an offshore wind power project, this technology successfully withstood high humidity and salt erosion, with the equipment operating continuously for 3 years without failure.

3. Full Life Cycle Testing System: Ensuring Zero-Defect Delivery

From raw materials to finished products, Jiaxun performs 100% full inspection on each RJ45 LAN Transformers including high-temperature aging (125℃/48h), mechanical vibration (20G acceleration), and lightning surge (6kV/3kA) tests. Data shows that after aging screening, the on-site failure rate is reduced to below 0.02%.

Chapter 3: Comparative Experiment of Industrial-Grade and Ordinary LAN Transformers

To verify the reliability of industrial-grade products, Jiaxun's laboratory conducted comparative tests on mainstream products on the market: RJ45 LAN Transformers

High-temperature and high-humidity test (85℃/85%RH): Ordinary products showed core cracking after 72 hours, while industrial-grade samples showed no performance degradation after 1000 hours; :The magnetic core of ordinary products cracks after 72 hours, while the industrial-grade samples show no performance degradation after 1000 hours.

Vibration test (10-2000Hz random vibration): The industrial-grade packaging structure reduces the risk of solder joint detachment by 90%; :

Cost-benefit analysis: Although the unit price of industrial-grade products is 15% higher, their 5-year comprehensive maintenance cost is only 1/3 that of ordinary models.

A smart warehousing company once experienced communication interruptions in its AGV vehicles due to the use of inferior LAN Transformers, resulting in daily losses exceeding 200,000 yuan. After replacing them with Jiaxun industrial-grade RJ45 LAN Transformers the system MTBF (mean time between failures) increased to 80,000 hours, and the failure rate decreased by 98%.

Chapter 4: Jiaxun Industrial-Grade LAN Transformer Solution Recommendations

1. Core Product Technology Advantages

JX-IGBT series industrial-grade RJ45 LAN Transformers supports PoE++ (90W power supply), 2.5G/5G Ethernet protocols, operating temperature -55℃~150℃, and is compatible with mainstream switches from Huawei, Cisco, etc.;

Customized services provide pin definition modification, integrated shielding shell design, and prototype completion within 72 hours.

2. Industry Benchmark Cases

State Grid's ultra-high voltage converter station project: Using 2000 Jiaxun RJ45 LAN Transformers, achieving 5 years of zero-failure operation in a strong electromagnetic interference environment;

German automotive production line transformation: Through customized anti-vibration models, the equipment restart time was reduced from 30 minutes to 5 seconds.

3. Customer Value Commitment

Free testing support provides 3 sample sets and an "Industrial Scene Adaptability Test Report";

Rapid response mechanism the technical team connects with needs within 15 minutes and provides solutions within 48 hours;

Ten-year extended warranty promises "free replacement for quality issues, cost-price repair for non-quality issues".

Take Action Now

Contact customer service to obtain the "Industrial-Grade RJ45 LAN Transformer Selection White Paper" and a customized quotation plan. The first 20 consulting customers can apply for additional 1-on-1 expert diagnostic services!

RJ45 LAN Transformer ,LAN Transformer ,LAN Transformer manufacturer

30

2025-05

30

2025-05

Soaring Demand for Customized Ethernet Transformers: How Can Chinese Manufacturers Respond Quickly?

29

2025-05

29

2025-05

How do SMD LAN Transformers solve the problem of high-frequency signal attenuation?

29

2025-05

29

2025-05

Decoding Industrial LAN Transformers—3 Essential Manufacturing Processes for Premium Manufacturers

29

2025-05

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy