04

2025

-

06

China SMD LAN Transformer Supplier: Technology Leader in the Wave of Miniaturization

Author:

I. SMD LAN Transformers Technical Architecture and Performance Breakthroughs

1.1 Core Functions of Miniaturized Design

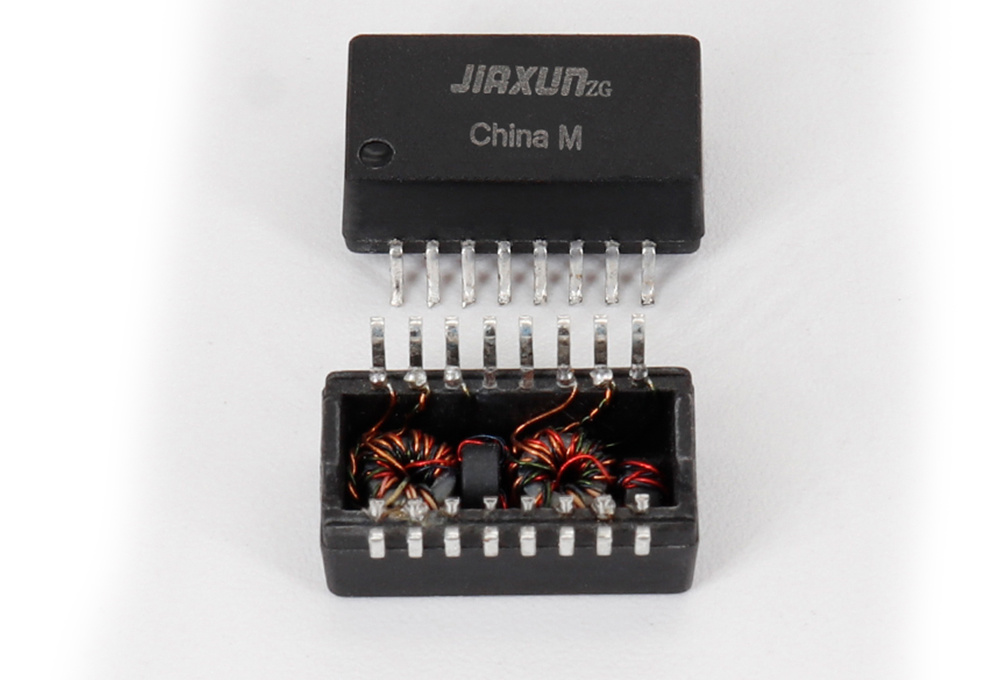

SMD LAN Transformers (Surface-Mount Device LAN Transformer), as the "invisible guardian" of modern electronic devices, integrates four key capabilities within a 4.8×3.2×2.5mm package:

High Voltage Isolation : Achieves 1200Vrms/min withstand voltage (UL certified standard) through Triple Insulated Wire.

Impedance Control : Employs a balanced dual-winding structure to maintain 100Ω±3% differential impedance (VSWR≤1.2).

High-Frequency Filtering : Common mode rejection ratio ≥50dB for 1MHz-2.5GHz noise.

High Temperature Resistance : Supports -55℃~+125℃ operating temperature (conforms to AEC-Q200 Grade 0 standard).

Leading Chinese SMD LAN Transformer Suppliers have achieved 0201 ultra-miniature packaging technology, integrating complete electromagnetic isolation functionality within a 0.6×0.3×0.25mm space, reducing volume by 90% compared to traditional plug-in transformers.

1.2 Comparison of Technical Parameter Evolution

| Parameter | 2018 Standard | 2024 Benchmark | Upgrade Benefits |

| Package Size | 6.0×5.0×3.2mm | 3.2×2.5×1.8mm | Volume reduced by 72% |

| Operating Frequency | 100MHz | 600MHz | Supports 10G Ethernet |

| Insertion Loss | 0.8dB | 0.25dB | Improved Signal Integrity |

| Automated Placement Speed | 20k units/hour | 85k units/hour | Production Efficiency ×4.25 |

II. Chinese SMD LAN Transformer Suppliers Global Competitiveness

2.1 Technical R&D System Construction

Leading Chinese SMD LAN Transformer Suppliers established a three-dimensional technical moat:

Material Innovation : Development of Low-Temperature Co-fired Ceramic (LTCC) substrates, with thermal expansion coefficient matching PCB to ±0.3ppm/℃.

Process Breakthroughs : Laser micro-via winding technology achieves 0.02mm wire diameter with ±0.1 turn accuracy.

Testing and Certification : Equipped with Vector Network Analyzer (VNA) and Eye Diagram Test System.

The HX-TF0805 series developed by a leading enterprise in Guangdong has a jitter of only 3.2ps at a 10Gbps transmission rate, becoming a core supplier for Huawei's 5G AAU modules.

2.2 Advantages of Intelligent Manufacturing Ecosystem

SMD LAN Transformer Suppliers achieved through digital transformation:

Smart Factory : 16 fully automated production lines achieve a 72-hour closed loop from raw materials to finished products.

Process Control : AI vision inspection system identifies 0.015mm welding defects.

Flexible Supply : Supports quick switching between 12 package types such as 0402/0603/0805.

Industry data for 2023 shows that Chinese suppliers in Global SMD LAN Transformer market share jumped from 28% to 47%, with high-frequency (≥500MHz) products accounting for over 35%.

III. Multi-domain Application Scenarios and Value Creation

3.1 5G Communication Infrastructure

For AAU RF unit requirements, Chinese SMD LAN Transformer Suppliers provides:

Broadband Design: Covers 3.5GHz±500MHz frequency band.

Low Insertion Loss Solution: Insertion loss ≤0.3dB@6GHz.

Anti-corrosion Treatment: Passed 96-hour double 85 test (85℃/85%RH).

Tests by an equipment vendor show that after using domestic components, the base station signal distortion rate decreased from 1.8% to 0.5%.

3.2 Industrial Automation Control

Industrial-grade SMD network transformers feature:

Vibration Resistance Design: Passed 20G random vibration test (IEC 60068-2-64).

Three-Proof Coating: Moisture-proof/Mildew-proof/Salt spray resistance up to IP67.

Fast Response: -40℃ cold start time <0.5 seconds.

Schneider Electric adopted domestic products in its smart factory project, reducing PLC module failure rate by 58%.

3.3 Consumer Electronics and Automotive Electronics

Miniaturized innovative solutions include:

0.8mm ultra-thin design for TWS earbud charging cases.

Automotive-grade products meet ISO 16750-3 mechanical shock standards.

Supports 20Gbps high-speed transmission with USB4 interface

After BYD's in-vehicle Ethernet modules adopted domestically produced SMD transformers, the EMC certification pass rate increased from 88% to 99%.

IV. Industry Trends and Procurement Strategy Optimization

4.1 Technology Evolution Directions

High-frequency : Developing transformers supporting 56G PAM4 signals (bandwidth ≥28GHz)

Integration : Module solution co-packaged with RJ45 connectors (size reduction 40%)

Intelligentization : Self-protecting products with built-in NTC temperature sensors

Chinese enterprises have mass-produced SMD transformers based on gallium nitride materials, with operating frequencies exceeding 1GHz.

4.2 Supplier Evaluation Dimensions

Procurement decision-makers should focus on:

Process Certification : Verify compliance with IATF 16949 and IPC-A-610 standards

Delivery Capability : Verify feasibility of 15-day delivery for millions of units

Customization Services : Evaluate impedance tuning (±1%) and special coating processes

A certain cloud computing giant, by choosing Chinese SMD LAN Transformer Suppliers parked server NIC procurement costs by 32% and compressed delivery cycles to 7 days.

Chinese Supplier Competitiveness Matrix

| Indicator | International Manufacturers | Leading Chinese Enterprises | Advantage Gap |

| Unit Price | $0.45 | $0.28 | -37.8% |

| Minimum Package Size | 3.2×2.5mm | 2.0×1.6mm | Area -60% |

| High-frequency Product Yield | 96.5% | 99.3% | +2.8% |

| Patents Granted (last 3 years) | 850 | 2200 | +158% |

SMD LAN Transformer,SMD LAN Transformer Supplier

Previous Page

04

2025-06

04

2025-06

04

2025-06

30

2025-05

In-depth Comparison of LAN Transformer Suppliers: 7 Key Parameters Affecting Device Lifespan

30

2025-05

30

2025-05

Soaring Demand for Customized Ethernet Transformers: How Can Chinese Manufacturers Respond Quickly?

29

2025-05

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy