06

2025

-

06

Fiber Optic Modules — Core Technology Analysis and Market Outlook for Driving the Digital Future

Author:

Chapter 1: Optical Transceiver Modules Technical Definition and Core Functions

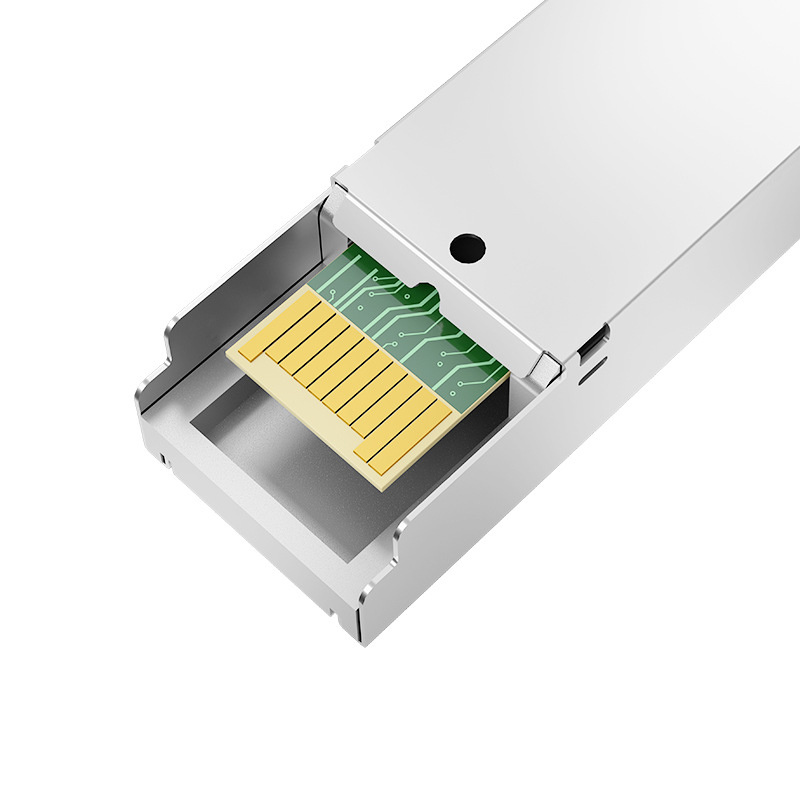

Optical Transceiver Modules An optical transceiver is an integrated device that converts optical and electrical signals. It consists of a laser, a photodetector, a driver circuit, and an optical interface. Its core functions include:

Photoelectric Conversion : Converts electrical signals into optical signals (transmitting end) or vice versa (receiving end);

Protocol Adaptation : Supports various communication protocols such as Ethernet and Fibre Channel (FC);

Rate Matching : Covers a rate range from 1Gbps to 800Gbps to meet bandwidth requirements in different scenarios.

According to the packaging form, optical transceiver modules can be divided into SFP optical modules (Small Form-factor Pluggable), QSFP (Quad Small Form-factor Pluggable), and OSFP (Octal Small Form-factor Pluggable), etc. Among them, SFP optical modules, with their compact size (20mm×10mm), hot-swappable design, and low power consumption (<1W), have become the preferred solution for enterprise-level network equipment.

Chapter 2: Optical Transceiver Modules Diverse Application Scenarios and Market Demand

Optical Transceiver Modules Applications have permeated core areas such as communications, data centers, and industrial control:

5G Base Stations : Front-haul (FH) and mid-haul (MH) networks require 25G/50G optical modules to achieve low-latency (<1μs) signal transmission;

Hyperscale Data Centers : 400G/800G optical modules support data exchange for AI computing clusters and cloud services, reducing single-rack power consumption by 30%;

Smart Factories : Industrial-grade optical modules (-40℃~85℃ wide temperature range) are used for PLC and machine vision systems, improving electromagnetic interference resistance by 50%.

According to LightCounting's forecast, the global optical module market will exceed US$20 billion in 2025, with Chinese suppliers accounting for over 40%. Due to their strong compatibility and controllable costs, SFP optical modules continue to dominate the small and medium-sized enterprise market.

Chapter 3: Optical Transceiver Modules Technical Advantages and Competitiveness Analysis

Compared to traditional copper cables, Optical Transceiver Modules the core advantages are reflected in three aspects:

Ultra-high Bandwidth : Single-mode fiber transmission distance can reach 80km (100G LR4), far exceeding the 100m limit of copper cables;

Anti-interference : Optical signals are not affected by electromagnetic noise, ensuring data integrity in sensitive scenarios such as finance and healthcare;

Energy Efficiency : 100G optical module power consumption is reduced by 60% compared to copper cable solutions of the same speed, meeting the needs of the "dual carbon" strategy.

SFP optical modules Further strengthening competitiveness:

Plug and Play : Supports online replacement, reducing network maintenance downtime;

Multi-rate Compatibility : Adaptive 10G/25G rate switching through the digital diagnostic interface (DDM);

Cost Advantage Chinese optical module manufacturers have reduced the price of SFP modules to 70% of that of their European and American counterparts through domestic chip production.

Chapter 4: Production Process and Quality Control of Optical Transceiver Modules

Optical Transceiver Modules Manufacturing integrates precision optics and semiconductor technology, with key processes including:

TO-CAN Packaging : Coupling the laser chip (DFB/EML) and lens to a metal can, with airtightness reaching 10⁻⁸ Pa·m³/s;

COB Bonding : Using gold wire bonding technology to connect the driver IC and PCB, with positioning accuracy of ±1μm;

Optical Alignment : A six-axis automatic core alignment machine calibrates the fiber and optical path, with coupling efficiency >95%;

Aging Test : High-temperature (85℃) full-load operation for 500 hours to screen out early failures.

To improve yield, leading manufacturers have introduced AI optical inspection systems to automatically identify defects such as spot offset and solder joint voids, controlling the factory defect rate to below 0.05%. Chinese optical module manufacturers companies, through vertical integration of TOSA/ROSA (optical transmitter/receiver sub-modules) production lines, have reduced the delivery cycle to 15 days, significantly enhancing their global supply chain influence.

Conclusion

From the Gigabit to the Terabit era, Optical Transceiver Modules has always been the engine of digital infrastructure upgrades. With the implementation of new technologies such as CPO (Cose-Packaged Optics) and LPO (Linear Drive Pluggable Optics), the industry will usher in a new round of reshuffling. Chinese optical module companies, with their process innovation and agile delivery, are expected to further expand their leading advantage in the 800G/1.6T track, providing global customers with higher-density, lower-power interconnection solutions.

06

2025-06

06

2025-06

SFP Optical Module—The Core Engine and Market Opportunities of High-Speed Network Interconnection

06

2025-06

SFP Optical Module—The Core Engine and Market Opportunities of High-Speed Network Interconnection

06

2025-06

Fiber Optic Modules — Core Technology Analysis and Market Outlook for Driving the Digital Future

04

2025-06

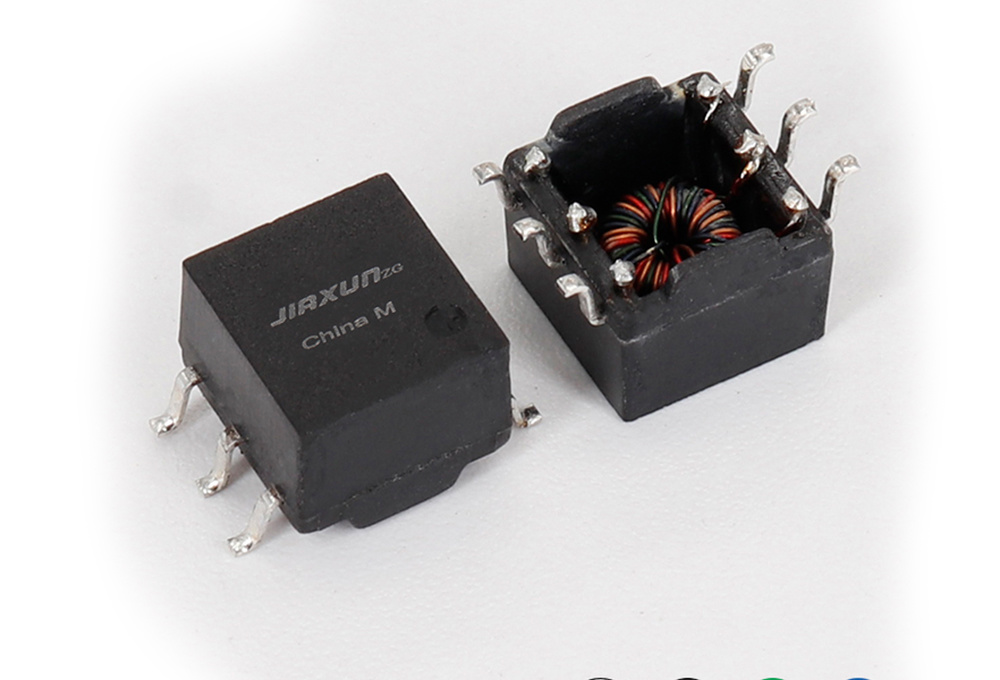

China SMD LAN Transformer Supplier: Technology Leader in the Wave of Miniaturization

04

2025-06

04

2025-06

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy