09

2025

-

06

Smart LED Drivers: Core Technologies and Future Applications Reshaping the Future of Lighting

Author:

Chapter 1: Intelligent LED Driver Technical Definition and Core Functions

Intelligent LED Driver It is a power management device integrating a digital control module, specifically designed for LED lighting systems. Unlike traditional drivers, it has a built-in microprocessor and communication chip, supporting multiple control methods such as PWM (Pulse Width Modulation) dimming, 0-10V voltage regulation, and DALI protocol. It can adjust brightness and color temperature in real-time according to ambient light, user needs, or preset scenes. For example, in smart homes, users can remotely set lighting modes through mobile APP or voice assistants; in commercial scenarios, the system can be linked with sensors to achieve automated management of lights turning on when people arrive and off when they leave.

As a core competency of intelligent LED driver manufacturers These products also have overvoltage protection, short-circuit protection, and temperature monitoring functions to ensure long-term stable operation. At the same time, its compatibility design can adapt to different brands of lamps, significantly reducing the complexity of system integration, and becoming a key to infrastructure upgrades in areas such as smart cities and Industry 4.0.

Chapter 2: Intelligent LED Driver Four Core Advantages

1. Energy-efficient and highly efficient, reducing operating costs

Intelligent LED Driver By dynamically adjusting power output, energy consumption can be reduced by 30%-50%. For example, in office scenarios, combined with human body sensing technology, the lighting system only operates at full power when needed, avoiding unnecessary power consumption.

2. Flexible control, enhancing user experience

Supports multiple communication protocols such as Zigbee, Bluetooth, and Wi-Fi. Users can customize lighting scenes (such as meeting mode, rest mode) to meet diverse needs. Manufacturers can also provide SDK interfaces to help customers develop exclusive control platforms.

3. Long lifespan and low maintenance costs

Using industrial-grade components and heat dissipation optimization design, the average Mean Time Between Failures (MTBF) exceeds 50,000 hours, significantly reducing the frequency of equipment replacement.

4. Data-driven, empowering intelligent decision-making

Some high-end models have built-in data acquisition modules that can collect energy consumption, usage time, and other information, providing a basis for enterprises to optimize energy management.

These advantages make Intelligent LED Driver it the preferred solution for commercial complexes, warehousing and logistics, road lighting, and other scenarios.

Chapter 3: Intelligent LED Driver Diverse Application Scenarios

Commercial Lighting

In shopping malls, hotels, and other places, intelligent LED drivers can be linked with Building Management Systems (BMS) to adjust lighting intensity according to crowd density, and create a festive atmosphere through color temperature changes, enhancing the consumer experience.

Industrial and Municipal Lighting

Factory workshops require highly stable lighting. The driver, with its IP67 protection level and anti-interference design, ensures reliable operation in harsh environments; while smart streetlights rely on the driver's remote group control function to achieve single-lamp fault alarms and regional energy-saving strategies.

Home and Health Lighting

By simulating the natural light cycle, intelligent LED drivers can regulate the human circadian rhythm and improve sleep quality. Some manufacturers also offer medical-grade products for shadowless lamps in hospitals and phototherapy equipment in rehabilitation centers.

Agriculture and Plant Factories

According to the growth needs of different crops, the driver can precisely control the spectral ratio to accelerate photosynthesis, verifying the potential of cross-border technology integration.

Chapter 4: Intelligent LED Driver Manufacturing Process and Quality Control

First-class a core competency of intelligent LED driver manufacturers Usually uses fully automated SMT (Surface Mount Technology) production lines to ensure that the placement accuracy reaches ±0.01mm. Core processes include:

Design and Development Stage : Optimizing circuit layout through thermal simulation and EMC testing to avoid electromagnetic interference;

Component Selection : Using high-efficiency ICs from brands such as TI and Infineon, combined with low-ESR solid-state capacitors;

Assembly and Testing : Completing potting and sealing in a constant temperature and humidity workshop, and conducting a 72-hour aging test;

Quality Control : Implementing international certification standards such as IEC61347 and ENEC, with traceable data retained for each batch of products.

In addition, some manufacturers introduce AI quality inspection systems to automatically identify welding defects through machine vision, controlling the defect rate to below 0.1%. This strict quality control system ensures the stability of the product in a wide temperature range of -40℃ to 85℃, meeting the needs of global customers.

Conclusion

With the deep integration of IoT and AI technologies, a core competency of intelligent LED driver manufacturers will continue to drive innovation and iteration in the lighting industry. From energy saving and efficiency improvement to scene-based services, this technology is redefining the value boundaries of "light," providing underlying support for smart cities, green buildings, and other fields. Choosing partners with core R&D capabilities and large-scale production will become a key strategy for enterprises to seize the smart lighting market.

Smart LED Driver,Smart LED driver manufacturer

09

2025-06

09

2025-06

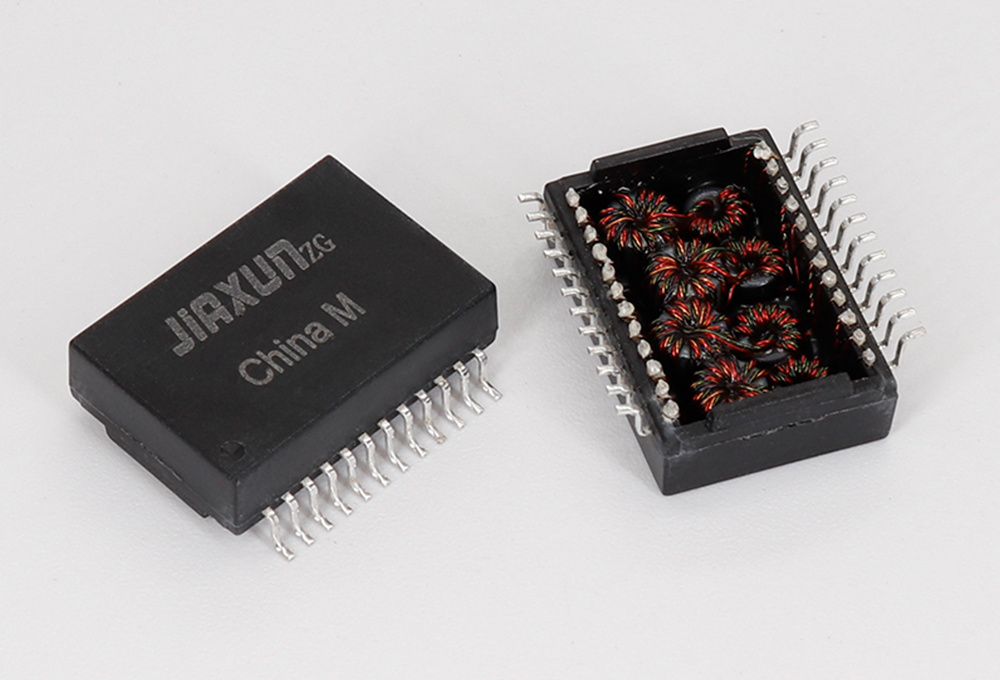

RJ45 Jack Module - Core Component of Network Connection and Wholesale Value Analysis

09

2025-06

PLC Power Supply: Reliable Power Source and Technological Innovation for Industrial Automation

09

2025-06

Smart LED Drivers: Core Technologies and Future Applications Reshaping the Future of Lighting

07

2025-06

Gigabit RJ45 Connector—The Cornerstone and Selection Guide for Stable Networking

07

2025-06

RJ45 Jack Supplier Guide: Technical Analysis and Innovation Solutions from Jiaxun Smart Technology

07

2025-06

Gigabit RJ45 Connector — Core Components and Selection Guide for Enterprise Network Upgrades

Contact Us

Factory add: NO.54. Jinhu South Road, Chenjiang Town, Zhongkai Hi-tech Zone, Huicheng District, Huizhou city, China

Telephone:0752-2099791

Office add: B901-1, Silver Star Hi-Tech Building, No. 1301 Guanguang Road, Longhua District, Shenzhen, China

Website:www.jiaxunzg.cn

Telephone:0755-81752121

Fax: 0755-81752963

Mailbox:sales1@jiaxunzg.cn

Mailbox:sales2@jiaxunzg.cn

Mailbox:sales3@jiaxunzg.cn

Copyright © 2024 Jiaxun (Huizhou) Intelligent Technology Co., Ltd. Privacy Policy